In Finland, around 8,000 buildings are demolished annually. According to unofficial estimates, up to 500,000 buildings are demolished in the EU and 200,000 in the US each year.

Dismantled buildings account for 85% of construction and demolition waste in Finland. The nation is committed to recycling or reusing 70% of that waste, yet the current utilization rate remains under 60%. From a circular economy perspective, we lose vast amounts of construction materials and components that could be reused rather than burned or used as backfill.

I did my first podcast interview about circularity ten years ago. Since then, circularity in construction has advanced, but practical applications remain far from mainstream. However, new initiatives like the ReCreate project are finally providing the technical and digital frameworks needed to close this gap.

Adaptability and reassembly of buildings

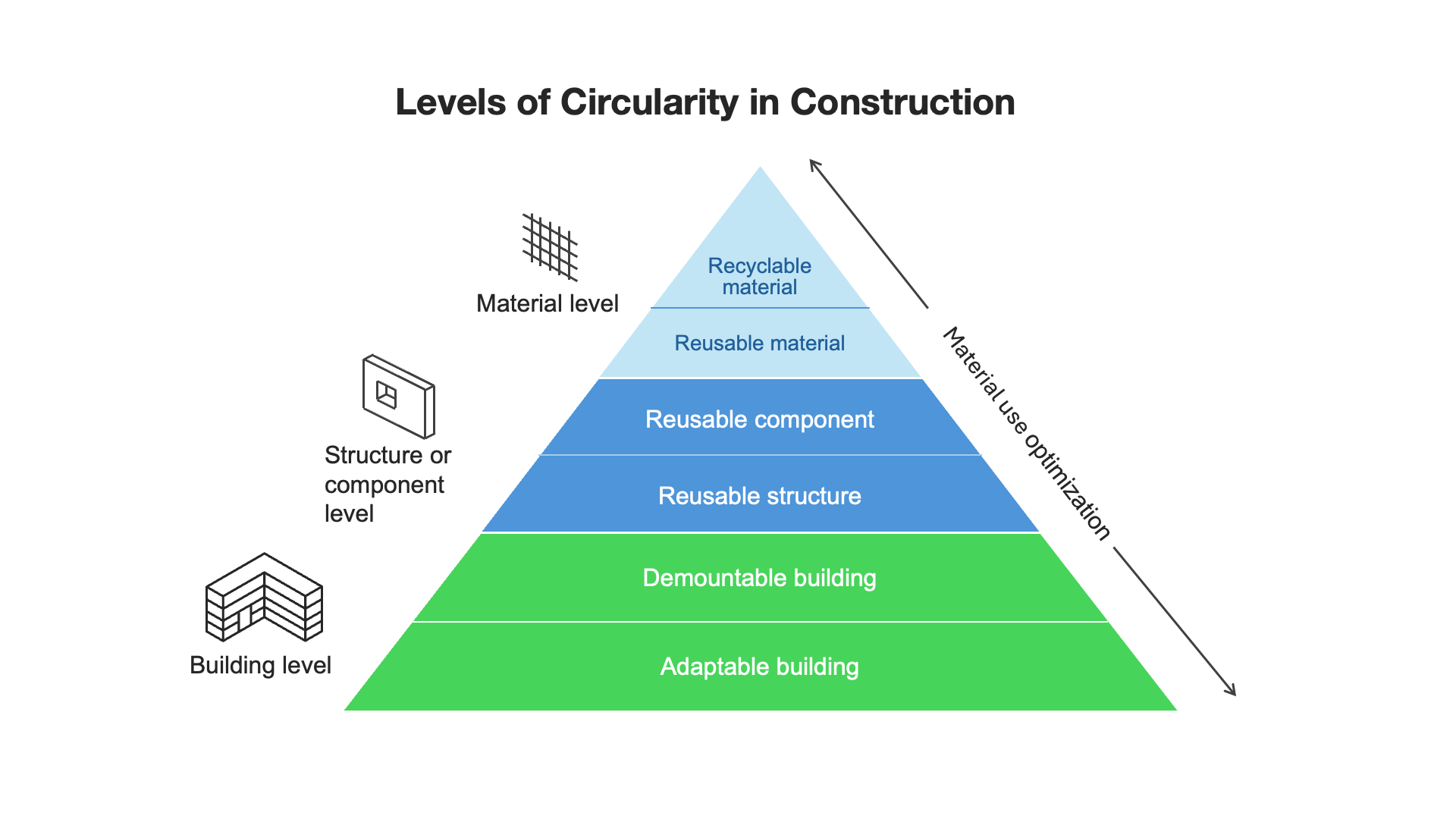

There are various strategies for achieving circularity. If buildings were originally designed and built for adaptability, a full demolition would not be necessary. The core and shell could be retained while the other parts would be remodeled for new purposes.

Alternatively, a building can be designed for dismantling and reassembly. A temporary courthouse built in the Netherlands in 2016 was dismantled after five years of use, and its components were stored for future reassembly.

Similar projects have been carried out in Finland and Sweden. The components of Espoo’s Pikkulaiva commercial building were sold for reuse after demolition, and Stockholm’s Östermalm temporary market hall was reassembled in Mölnlycke as a restaurant and padel hall.

Reuse of prefab concrete components

The majority of modern Finnish apartment and office buildings have been constructed using prefabricated concrete floor slabs, walls, and facades. Many buildings from the 1960s through 1980, and even later, are being demolished because they no longer serve their original purpose or are too expensive to renovate.

Until now, the reuse of precast structural components has been almost nonexistent in Finland. That might change soon, thanks to the ReCreate project.

Recreate is a four-year, EU-funded Horizon project that began in 2021. Participants are from Finland, Sweden, the Netherlands, Germany, and Croatia. The project aims to determine how used concrete components can be deconstructed without damage so they can be reused in new buildings and to turn the process into a profitable business.

New methods and pilots

The project comprises several pilot projects that explore the deconstruction and reassembly of concrete components. ReCreate also develops standardized, low-cost, and non-destructive testing methodologies to certify the structural integrity and safety of salvaged components.

ReCreate offers novel architectural design practices and engineering techniques tailored to the constraints of using existing, fixed-dimension salvaged elements. It also addresses the data aspect of circularity by integrating BIM with RFID tagging. Each physical element is paired with a digital twin that tracks its history, quality data, and technical specifications throughout the deconstruction and reassembly process.

The Finnish partners have carried out several pilot projects. The first one took place in Tampere, where salvaged hollow core slabs were installed in an apartment building. Another pilot reused structural components during the construction of Metso’s Lokomotion technology center.

Skanska Finland’s regional manager, Toni Tuomola, said in an interview with Rakennuslehti magazine that installing salvaged components does not differ significantly from installing new equivalents. Raine Hakala, project director at Umacon, noted that the disassembly process must be careful yet efficient to make reuse economically feasible.

Project-driven and industry-driven circularity

Last year, I interviewed Robert van den Brink, a doctoral researcher at Aalto University working at VTT, about circularity for construction. He stated that the greatest challenge for circular construction is establishing a stable, commercially viable supply of recycled or reusable materials.

Robert explained that the circular economy can be implemented in construction in two ways: project-driven and industry-driven.

In the project-driven approach, the client may require that circular economy principles be applied to a project, for example, by reusing structures or materials. Designers and contractors then determine how this will be achieved. Robert noted that this is the dominant practice today, although it is neither particularly cost-effective nor scalable.

In the industry-driven model, material and product manufacturers take responsibility for, for example, the use of recycled materials. From the project’s perspective, nothing necessarily changes; only product declarations reveal the origin of materials. This model is scalable, provided manufacturers can keep product prices at conventional levels.

From vision to commercial feasibility

In the target state, construction stakeholders can commit to using recycled products from the early stages of projects. Designers receive accurate information on the properties of recycled products and can rely on their availability. Contractors can price materials in tenders without risk premiums and receive them on site in a timely manner.

We are nowhere near this vision. Projects like ReCreate are necessary, but we need an industry-wide systemic change to make circularity a commercial success. Recent Finnish developments in product data management demonstrate that we have the knowledge and technology to take the leap.

The circular economy is no longer optional; it is the new baseline for European building standards.

View the original article and our Inspiration here

Leave a Reply