Six businesses have made the shortlist for Digital Consultancy of the Year at the Digital Construction Awards 2026.

Traditional, manual surveys provide only a partial picture of onsite materials, making it difficult to manage the materials management plan (MMP) effectively. Inaccurate volume calculations lead to costly over- or underordering of aggregates, inefficient reuse of material, and compliance challenges with environmental regulations. These risks are exacerbated on large developments, which often comprise hundreds of plots.

Each drone flight collects high-density survey data across the whole site. This is processed into an accurate digital terrain model and orthomosaic imagery, then run through a volumetric analysis workflow to calculate the volume of every accessible stockpile. Drone Surveying’s in-house engineers enrich the dataset, naming and categorising each stockpile (eg topsoil, subsoil), tagging location and intended use, and aligning outputs with the client’s MMP. This provides a clear, auditable record of materials and supports planning and environmental compliance.

Drone Surveying’s customers also report improved confidence in material quantities, delivering cost savings of up to 20% in aggregate management and haulage. Drone data collection also removes the need for operatives to climb or walk stockpiles, reducing exposure to slips, trips and vehicle movements. Clear records of surveys, volumes and stockpile histories provide robust evidence for CDM duties and planning conditions, supporting both safety governance and regulatory compliance.

Working with Solving Construction, CITB, North London Loft Rooms and RLB Digital, Limes designed a curriculum that balanced strategic awareness with hands-on application. The programme was structured around two elements: an in-person launch event that involved live discussions, a demonstration day and a wrap-up session; and a series of online modules that allowed attendees to build skills progressively, supported by curated vendor content, case studies and a series of workbooks.

Key to the approach was ensuring the technology was not demonstrated but contextualised. For example, rather than simply showcasing software, Limes walked participants through how it could resolve everyday pain points such as tendering, site capture, programme planning and cashflow management. Before even touching on technology, Limes walked businesses through key principles of time management, process mapping, change management and continuous improvement to ensure that tools wouldn’t just be purchased and forgotten, but would address real needs and then be introduced and ‘stick’ within their businesses.

For the participating SMEs, the programme delivered tangible, measurable benefits. Attendees’ confidence in adopting technology nearly doubled on a measured scale before and after the programme. Builders reported clearer workflows, improved collaboration and significant time savings. One company calculated that, by digitising its estimating and programme planning, it had reduced time spent on tendering by 15%. Another saw a huge reduction in overheads by simply rationalising its tech stack and using what it had available, saving the firm around £10,000 per annum.

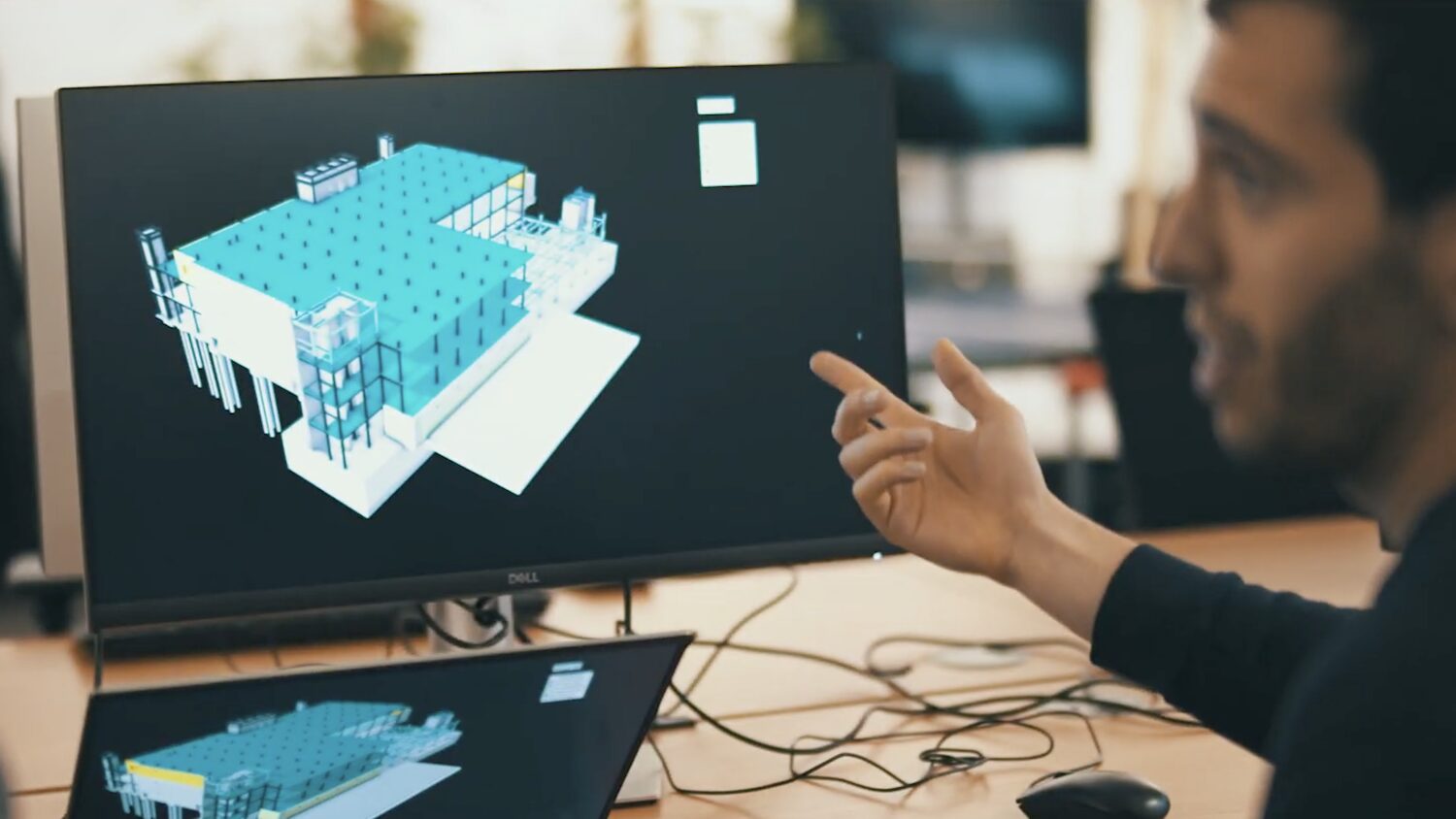

Programmatic rules, such as coverage requirements, device placement and system integration, are defined in code and automatically translated into constructible drawings. This approach not only improves efficiency, but also transforms quality: specifications become testable, traceable and extensible, reducing ambiguity and improving collaboration between disciplines.

Rapidly growing electrical engineering specialist H&MV Engineering brought in WiiGroup to help it overcome its information management obstacles. Key functions such as commercial, planning, quality, safety and procurement operated largely in isolation, relying on spreadsheets and manual reporting. These disconnected processes created inconsistent data, duplication of effort, and a lack of real-time insight for both site teams and executives.

The challenge for WiiGroup was how to combine and deploy them effectively within a fast-scaling, multi-departmental organisation while reshaping workflows and embedding a digital-first culture. Resistance to change was anticipated, so WiiGroup adopted a co-design model – engaging users early through workshops and agile sprints, gathering feedback and iterating rapidly. This approach built confidence, reduced risk and ensured that each department saw its role in shaping the solution, turning potential resistance into engagement.

The result was the H&MV Performance Hub – a replicable, centralised data ecosystem built on Microsoft Fabric, integrating Power Platform tools to streamline data capture, reporting and insight generation. Information from multiple departments and regions now flows into a single, structured architecture. Role-specific Power BI dashboards provide real-time visibility into project performance, cost reporting, schedule health and delay analysis, while Power Apps and automated templates standardise data entry and eliminate manual reconciliation.

Data discrepancies have fallen by 80%. Reporting that once required days of manual consolidation is now completed instantly, cutting reporting effort by 35% – equivalent to roughly 3,600 staff hours saved every month. Live dashboards provide engineers, project directors and executives direct access to critical KPIs, increasing cross-departmental visibility by 70%, and allowing decision-makers to see the full project portfolio at a glance.

View the original article and our Inspiration here

Leave a Reply