Decorative concrete has come a long way. What was once viewed as just a decorative overlay or backyard patio upgrade is now a key player in modern construction. Today, it’s not only about adding visual interest — it’s about combining aesthetics, performance and sustainability in one versatile material that’s showing up everywhere from retail interiors to public infrastructure.

As we look ahead to 2026, decorative concrete is entering a new era — driven by smarter materials, rising design expectations and a growing emphasis on environmental responsibility. These shifts are reshaping what’s possible on the jobsite and raising the bar for craftsmanship and creativity.

Realistic Finishes That Rival Nature

A major force driving decorative concrete forward is its unparalleled ability to replicate the look and feel of natural materials. Today’s form liners, silicone molds and hybrid overlays create textures so realistic that even trained professionals can mistake them for real stone, hardwood, or slate.

These finishes are particularly in demand for exterior applications such as outdoor kitchens, pool decks, retaining walls and walkways — areas where aesthetics must blend seamlessly with extreme durability. In climates where freeze-thaw cycles, de-icing salts, or UV exposure challenge natural materials, realistic decorative concrete offers an ideal substitute.

This realism doesn’t stop at surface texture. Artisans are refining techniques like hand scoring, multi-tone staining, and faux grouting to emulate mortar joints, wood grain weathering, and even fabric draping. When paired with thoughtful design and expert application, these methods allow contractors to deliver surfaces that look handcrafted — yet outperform the materials they mimic.

A Shift Toward Nature-Inspired Colors

The color narrative is increasingly informed by natural landscapes and subdued, earthy aesthetics. These tones aren’t achieved with a single product. Advanced layering methods — integral coloring in the base concrete, followed by semi-transparent stains, dyes, and reactive densifiers — are needed to develop a nuanced surface variation that mimics nature. This requires technical skill and an artist’s eye.

Project teams are also focusing more on consistency across surfaces exposed to different light, moisture, or wear conditions. Contractors are adapting by developing standardized mockups, color libraries and test panels to help clients visualize subtle shifts and make selections early in the design process. This not only improves design outcomes but also reduces costly change orders later.

Low-Sheen Sealers with High Performance

Sealer preferences increasingly lean toward soft, non-reflective finishes like matte and satin sealers, which better align with architectural trends favoring raw, authentic materiality. But aesthetics are only part of the story. Technological improvements have yielded water-based, breathable sealers with high abrasion resistance, excellent UV stability and low VOC content. They provide long-term performance in both interior and exterior settings while complying with tightening environmental regulations.

Concrete contractors who understand the chemistry behind products such as silane/siloxane penetration, acrylic versus polyurethane film formation, or the effect of surface porosity on cure behavior are better equipped to recommend the right product for each environment. In certain high-stakes applications like food service or healthcare, where chemical resistance and slip ratings are critical factors, this level of expertise adds measurable value.

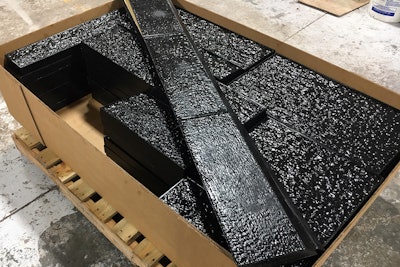

Decorative overlays continue to grow in popularity as a cost-effective, sustainable way to refresh aging surfaces. The Euclid Chemical Company

Decorative overlays continue to grow in popularity as a cost-effective, sustainable way to refresh aging surfaces. The Euclid Chemical Company

Overlays Offer New Life Without Demolition

As budgets tighten and sustainability metrics grow, overlays are becoming the go-to solution for revitalizing concrete surfaces to be aesthetically pleasing and functional while preserving the original slab — whether rejuvenating cracked driveways or transforming dull commercial interiors.

Stampable overlays up to 1/2-in. thick can accommodate deep textures and aggressive patterns, while microtoppings just millimeters thick are ideal for interior spaces requiring a modern, polished look. Self-leveling overlays with metallic pigments or integral colors are expanding the design vocabulary even further, especially in commercial showrooms and hospitality spaces.

Key to this success is surface preparation. Moisture vapor emission, residual coatings, and surface profile all affect overlay performance. Moisture mitigation systems, shot blasting, and the use of bonding primers tailored to overlay type are critical steps. Educating clients on why prep is non-negotiable helps to justify these costs while preventing premature failures.

Green Building Goals Drive Material Choices

As the construction industry pursues lower embodied carbon and higher operational efficiency, decorative concrete is being embraced as a sustainable material. Its thermal mass, durability, and compatibility with natural lighting strategies make it ideal for passive and net-zero designs.

Decorative systems are being designed with sustainability from the mix stage onward. Replacing portland cement with SCMs like fly ash, GGBFS, or natural pozzolans reduces carbon impact. In some cases, carbon-sequestering admixtures or CO₂-cured overlays are being specified for municipal or institutional projects seeking ESG alignment. Water-based stains and sealers, low-VOC adhesives, and recycled content in pigments or aggregate also contribute to LEED credits and other certification goals.

Concrete contractors who are fluent in sustainability metrics and who can provide Environmental Product Declarations (EPDs) and Health Product Declarations (HPDs) are being invited earlier into the design conversation and are often seen as strategic project partners.  Precision textures made possible by CNC technology are redefining vertical decorative concrete.The Euclid Chemical Company

Precision textures made possible by CNC technology are redefining vertical decorative concrete.The Euclid Chemical Company

Custom Details Powered by Digital Tools

The fusion of digital design and physical material is rapidly transforming decorative concrete. CNC-cut form liners, laser-etched patterns, and even 3D-printed molds enable the production of intricate textures, customized graphic,s and site-specific narratives that were once impossible or too costly.

For architects, this means limitless design freedom when it comes to concrete applications. For contractors, it means mastering a new set of workflows—from file formatting and tool path planning to casting and finishing. Even when these services are outsourced, understanding the fabrication process allows for better collaboration and higher-quality results.

Low-gloss polished concrete floors offer a softer, more natural aesthetic while maintaining durability and easy maintenance.The Euclid Chemical Company

Low-gloss polished concrete floors offer a softer, more natural aesthetic while maintaining durability and easy maintenance.The Euclid Chemical Company

Softer Looks for Polished Interiors

Polished concrete remains a preferred option in commercial interiors due to its low maintenance and long service life. However, this aesthetic expectation has shifted from mirror-like reflectivity to more muted, satin finishes that feel warm and approachable.

Concrete contractors are achieving these looks by exposing lighter aggregates, using finer grit sequences, and minimizing densifier haze to create velvety surfaces that still meet commercial performance specs. The inclusion of local stone or custom seed materials in the initial pour allows projects to reflect regional identity, adding cultural or historical context.

Glow-in-the-dark aggregates bring decorative concrete to life after dark.The Euclid Chemical Company

Glow-in-the-dark aggregates bring decorative concrete to life after dark.The Euclid Chemical Company

Surfaces That Come Alive After Dark

With UV-reactive pigments, glow-in-the-dark aggregates and photoluminescent coatings, decorative concrete can now shift in appearance from day to night. These effects are increasingly being applied to pathways, entryways, patios and even vertical elements like signage or façade panels.

Proper execution requires understanding the charge and discharge rates of photoluminescent materials, selecting sealers that don’t block light absorption, and calibrating pigment loading to suit ambient light conditions. Though still considered niche, demand is growing—especially in hospitality, public parks, and entertainment venues where immersive environments drive user engagement.

Custom Branding Embedded in Concrete

A custom stamped logo showcases how decorative concrete can seamlessly blend branding and design.The Euclid Chemical Company

A custom stamped logo showcases how decorative concrete can seamlessly blend branding and design.The Euclid Chemical Company

These applications blend multiple techniques—engraving, stenciling, staining, and polishing—and require a strong grasp of layout planning, scale, and durability under foot traffic or environmental exposure. They also offer a high-margin opportunity with turnkey design and execution.

Skilled Labor Becomes a Competitive Asset

With new techniques and expectations comes a demand for more skilled labor. Decorative concrete now requires a hybrid skill set of aesthetic sensibility, materials science, environmental literacy, and digital fluency. While the labor gap is growing, it’s also an opportunity to invest in differentiation.

Internal apprenticeships, manufacturer-sponsored certifications, and cross-training across overlay, stamping, polishing, and sealing systems creates a workforce that is agile, informed, and deeply invested in project outcomes. More importantly, it positions your team as a value-adding partner on complex, high-visibility projects.

Contractors who market their team’s knowledge, not just the finish, are finding that clients are increasingly choosing expertise over the low bid.

As the lines between design, durability, and sustainability continue to blur, decorative concrete sits at a powerful intersection. Contractors who embrace this evolution and invest in both the craft and science behind decorative concrete will help shape the built environment for years to come.

View the original article and our Inspiration here

Leave a Reply