For centuries, natural stone has been the hallmark of luxury in commercial architecture. From the imposing granite pillars of a bank headquarters to the intricate marble floors of a five-star hotel lobby, stone commands respect. However, for general contractors and fabricators, working with these unforgiving materials has historically meant one thing: bottlenecks.

Traditional stone masonry is an art form, but it is also slow, labor-intensive, and prone to costly human error. In an era where construction schedules are tighter than ever and the skilled labor gap is widening, the industry is turning to a digital solution.

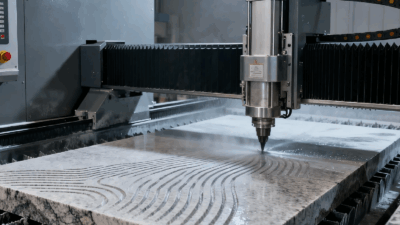

Enter the era of Stone CNC (Computer Numerical Control) Router Machines.

Here is why upgrading to automated stone fabrication is no longer just a luxury—it is a necessity for staying competitive in the modern renovation market.

The Intersection of Speed and Scalability

In commercial renovation, “time is money” is not a cliché; it is a contract clause. A delay in the fabrication of a custom reception desk can hold up the entire lobby completion.

Manual stone cutting relies heavily on the stamina and steady hand of the artisan. In contrast, CNC technology introduces tireless consistency.

- 24/7 Operation: Automated routers can run continuously with minimal supervision, drastically reducing lead times.

- Batch Consistency: Whether you are producing 10 vanity tops for a boutique hotel or 500 for a large resort, a CNC machine ensures the 500th piece is identical to the first.

By removing the variability of manual labor, fabricators can provide contractors with reliable delivery dates, a crucial factor in winning commercial bids.

Unlocking Complex Geometries and Design

Architects today are pushing boundaries. They want flowing curves, 3D relief textures, and intricate engravings that were previously too expensive or difficult to achieve with hand tools.

Modern stone CNC routers are not limited to straight cuts. They are capable of:

- 3D Engraving: Carving detailed logos, artistic patterns, or bas-relief designs directly into granite and marble.

- Precision Profiling: Creating complex edge profiles that are perfectly uniform.

- Nesting: Optimizing the layout of cuts on a slab to maximize material usage and minimize waste.

This technology bridges the gap between digital design (CAD/CAM) and physical reality, allowing fabricators to say “yes” to the most demanding architectural visions.

Mitigating Material Waste and Cost

Granite and marble are premium materials. One slip of a hand grinder can ruin a slab worth thousands of dollars.

CNC machines operate with microscopic precision. The automation ensures that cuts are executed exactly as programmed, virtually eliminating the risk of operator error during the cutting process. Furthermore, advanced software allows for better “nesting” of parts, ensuring you get the maximum yield out of every square foot of raw stone.

For a business owner, this translates directly to the bottom line: lower material costs and higher profit margins.

The Solution for Modern Fabricators

For fabrication shops and renovation contractors, the question is no longer if they should automate, but what equipment to trust. The market requires machinery that is robust enough to handle the sheer hardness of granite while being delicate enough for fine marble engraving.

Choosing the right machine involves looking at spindle power, frame rigidity, and software compatibility. It is about finding a partner that understands the specific demands of stone working.

If you are looking to upgrade your workshop’s capabilities or need to understand the technical specifications required for high-end stone work, it is essential to research the latest heavy-duty options available.

Explore the Technology: To dive deeper into the specific features that drive efficiency, read this comprehensive guide on Stone CNC Router Machines for Granite & Marble Engraving. It covers everything from machine structure to application versatility, helping you make an informed decision for your next capital investment.

Conclusion

The future of commercial construction is digital, and stone fabrication is catching up. By embracing CNC technology, businesses can deliver heritage-quality craftsmanship at industrial speeds. It is the perfect marriage of tradition and technology—ensuring that stone remains a cornerstone of commercial design for generations to come.

Frequently Asked Questions (FAQs)

Q1: Can Stone CNC routers cut all types of stone?

A: Yes, high-quality stone CNC routers are designed to handle a wide variety of materials, including granite, marble, quartz, sandstone, and artificial stone. The key lies in using the correct diamond bits and adjusting the cutting speed and water cooling systems appropriate for the material’s hardness.

Q2: Is it difficult to transition from manual fabrication to CNC?

A: While there is a learning curve involved with the software (CAD/CAM), modern machines are increasingly user-friendly. Most operators find that once the initial training is complete, the workflow becomes significantly smoother and less physically demanding than manual labor.

Q3: What makes a “Stone” CNC router different from a wood router?

A: A stone CNC router is significantly more robust. It features a heavier, more rigid frame to absorb vibrations from cutting hard materials. Crucially, it includes a water-cooling system for the tools and the stone to prevent overheating and dust, and the spindle usually has higher torque at lower speeds.

Q4: How does a CNC machine improve safety in the shop?

A: Automation keeps the operator at a safe distance from the cutting area. Additionally, because the cutting is done with water cooling (wet processing), it significantly reduces the amount of airborne silica dust, which is a major health hazard in traditional dry stone cutting.

Image source: Dinosaw Machinery

View the original article and our Inspiration here

Leave a Reply