I just listened to a fascinating interview on Bricks and Bytes with Jan-Hendrik Goldbeck, co-CEO of Goldbeck. The interview inspired me to raise a provocative question: Could vertical integration, similar to that of Goldbeck’s, be achieved virtually, without creating an “asset-heavy” conglomerate?

Vertically integrated construction

Goldbeck GmbH has spent over 50 years establishing itself as one of Europe’s most innovative construction firms, recognized for its integrated, technology-driven approach and focus on industrialized building methods.

Goldbeck specializes in modular construction by prefabricating 80–90% of the building components in its own plants. This system-based approach enables rapid, economical on-site assembly while allowing for high levels of customization, scalability, and consistent quality.

The company designs, constructs, and manages a variety of commercial buildings, including offices, logistics centers, and parking structures, as well as builds schools and residential developments.

From projects to products

An essential difference between Goldbeck and typical construction is productization. The company has successfully productized buildings and components, not as a one-size-fits-all solution but by systematizing its production.

Could the same be achieved virtually?

That would require a group of firms to invest in developing systematized products that could be applied to various scenarios. The product approach would offer repeatability, control, feedback, and optimization on a totally different level than typical one-off projects.

I believe that over 80% of buildings could be productized. Apartment buildings, data centers, and warehouses aren’t necessarily so unique that they can’t be systematized. With parameterized design, AI, and digital fabrication, they wouldn’t need to look like identical copies.

For clients, virtual vertical integration means fewer delays, clearer costs, and buildings that perform as promised. Because the design and delivery are based on proven product platforms, there is less risk of errors or rework, and the project runs more smoothly. Clients benefit from the efficiency of standardization without losing the ability to tailor solutions to their specific needs.

The technological basis

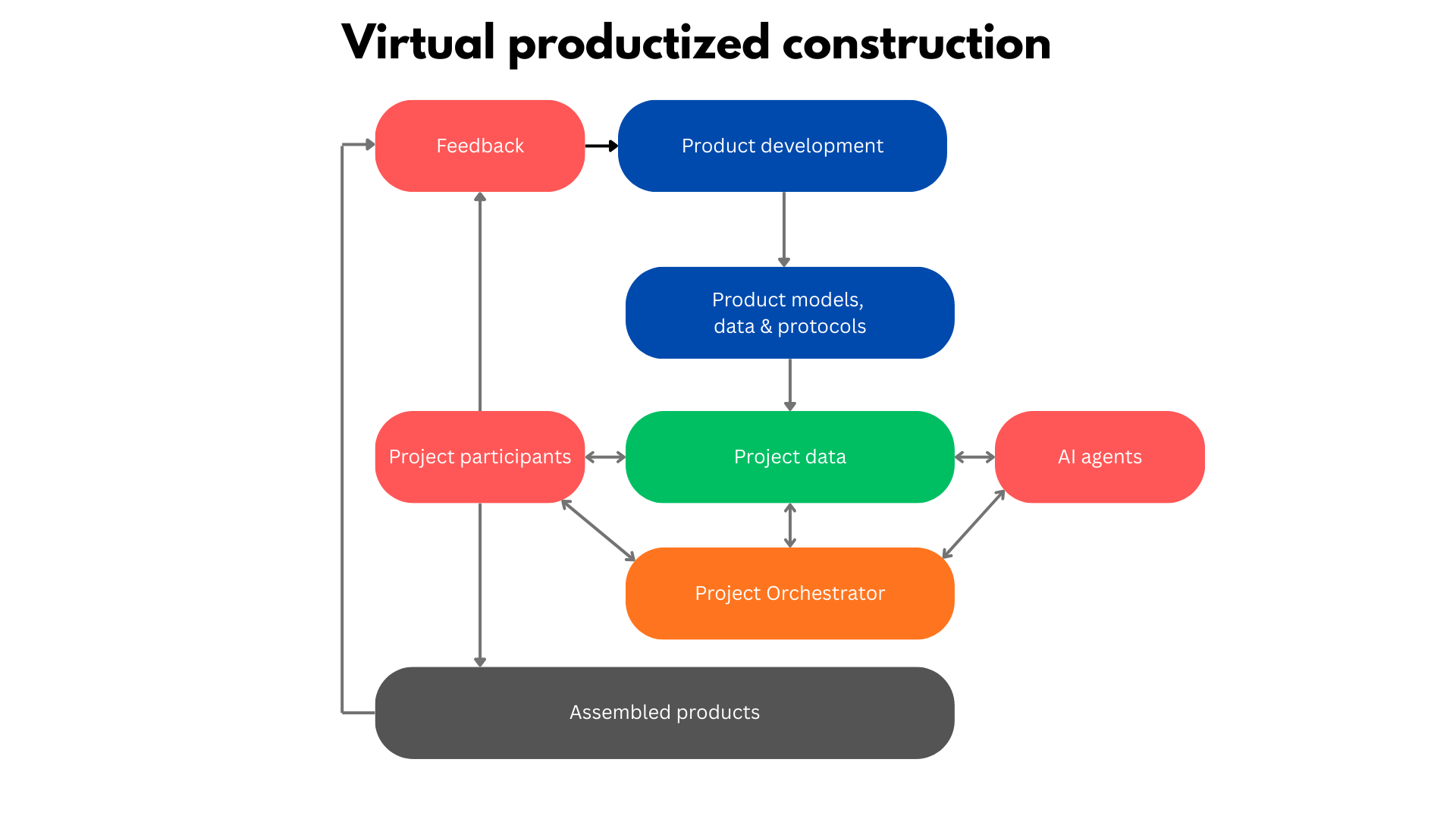

Instead of a single company handling everything, a network of specialized firms can operate as a single, integrated enterprise, coordinated through shared data, platforms, and protocols.

The virtual corporation applies the principles of BIM 2.0. It transforms BIM from a documentation and visualization tool into an intelligent, automated, and collaborative design and construction management environment powered by AI and real-time data flows.

Each company within the virtual corporation maintains its own data lake, and AI agents communicate using protocols like MCP and A2A.

The virtual enterprise adopts open data standards to enable efficient and automated collaboration. The systems share ontologies to ensure data is machine-readable and consistent across all platforms.

The business model

Technology alone, however, is not enough. The decisive factor is the business model.

Traditional design–bid–build delivery fragments responsibility and makes integrated product thinking impossible. Design-build is almost inevitable for virtual integration. This can be extended to design-build-manage, which further supports the product life cycle model.

A further challenge is product ownership. Even in a virtual enterprise, someone must hold design authority and bear liability. Without a clear custodian, disputes over intellectual property and accountability would quickly erode trust.

A possible solution is to establish a dedicated limited liability company that owns the product designs, the digital platform, and the intellectual property. Members of the virtual enterprise can hold stakes in this company, ensuring that those who invest in and rely on the platform also share in its governance and rewards.

Delivering the products

A productized company uses prefabrication and lean construction methodologies. With tight, standardized data-based integration, it removes variability of the product and the process.

A virtual enterprise orchestrator takes active responsibility for configuring and deploying the product platform in each project. This orchestrator could be a company within the consortium or a dedicated service arm of the LLC.

The company can also license the platform to projects and partners, creating a sustainable mechanism to fund continuous product development while providing legal clarity.

Next steps

Virtual vertical integration is not without hurdles. Independent firms must learn to trust one another, adopt common standards, and share data in ways that preserve both accountability and flexibility. This required training, transparency, and partnership-building.

Yet the reward is substantial: the efficiency of industrialized construction combined with the adaptability of networks. It provides a way for companies to grow their business, minimize waste, and accelerate innovation without duplicating Goldbeck’s capital-intensive process.

The shift requires not just technology and contracts, but also leaders willing to think beyond project silos and build trust across companies. The question is no longer whether the technology exists, but who will step forward to lead the first virtual productized company and gain the rewards.

View the original article and our Inspiration here

Leave a Reply