I attended the annual building services event, “Talotekniikka NEXT,” in Helsinki last Thursday. It was an afternoon filled with timely insights on topics ranging from preparing for national emergencies in design to the ethical guidelines of AI usage and the future of data center construction.

Everything we learned at the event highlights a key issue: data quality. Without reliable data, many of the great opportunities that new technologies offer won’t come to fruition.

The need for environmental data

One presenter, Granlund’s business development director Tytti Bruce-Hyrkäs (pictured), discussed the upcoming climate reporting requirements in Finland, which will become mandatory in 2026. New construction projects must submit a climate report and a building product inventory when applying for a building permit, along with a BIM model (IFC) of the project.

The permit applicant must list the building products used in the building and on the site known at the time of the permit application. Later, the inventory must be updated to include products whose selection was finalized during construction.

The greenhouse gas emission data must be compatible with or drawn from the national emissions database, EPDs (Environmental Product Declarations), or other reliable sources. The building product inventory and certain permit application materials must be machine-readable and follow national or otherwise regulated data models/data structures.

The state of data quality

Environmental reporting is a prime example of the need for trustworthy data in the construction industry. Another is waste management and achieving circularity.

A January 2025 report by Qualis Flow (Qflow) titled “The State of Data Quality in Construction” illustrates the challenges that the industry faces in ensuring data quality. The company analyzed six years’ worth of data from 445 construction projects, mostly from the UK, with some from the US and Australia. They incorporated 831,206 products and 195,178 waste removals.

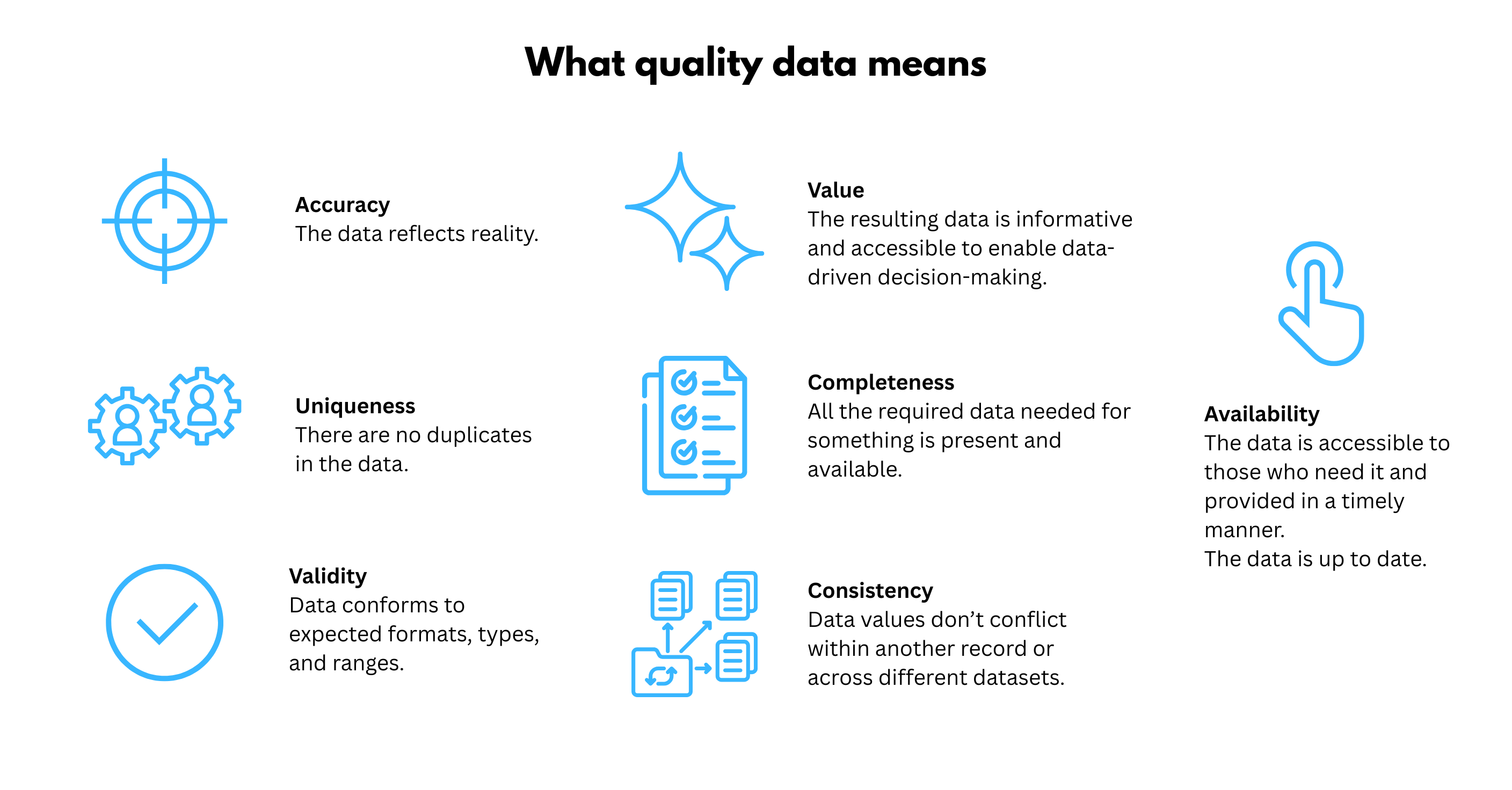

Qflow studied various aspects of data quality, such as accuracy, completeness, and consistency, focusing especially on waste removal documents.

Only 5% of the data was inaccurate; however, 95% was incomplete, with fields containing empty or incomplete information. 5% of the data were found to be duplicates, and 32% had invalid Standard Industrial Classification (SIC) codes. 66% of products lacked embodied carbon information.

One of the alarming shortcomings is related to standardization. 85% of the data needed standardization to create data consistency.

Attention to data quality pays off

The idea that we won’t require consistent and standardized data because AI can already read and understand messy documents is flawed. We should always strive to make data as structured and standardized as possible to save time and money and to avoid costly errors.

An often-quoted “1-10-100” rule-of-thumb states that it costs one unit to verify or structure data before its use, fixing errors detected later costs 10 units, and finding errors after decisions are made is ten times or more expensive.

If you’re early in a project, exploring options, or doing rough estimates, it might be acceptable to work with less structured data, because the cost of structuring everything might be higher than the cost of imprecision in that moment.

A change in the mindset is necessary

We often hear that data quality is everybody’s problem, but nobody wants to pay for it.

That mindset is holding the whole industry back. Data is not a free by-product; it’s part of the deliverable, just like concrete on site.

Fixing this requires systemic action: clients must specify and reward structured data in contracts, regulators must enforce standards, industry bodies must provide clear frameworks, and project teams must embed data quality into their daily workflows.

Only then can we stop treating good data as “extra work” and start seeing it as the foundation of safer, more efficient, and more sustainable construction.

PS. Bruce-Hyrkäs shared an interesting data point. Because buildings here in Finland are very energy-efficient, only 15% of the life cycle emissions of a modern school building come from energy use. 56% stem from material manufacturing, 17% from exchange of components, and 8% from transport and construction.

View the original article and our Inspiration here

Leave a Reply